We specialise in PCB population and assembly, from design to prototyping through to full volume production and assembly.

Prototyping

Draycote Technology offers a cost effective and flexible prototyping service.

A short run of assembled units can be produced relatively quickly in most cases. If required, we can advise on your choice of components and offer guidance on making the finished item as cost effective as possible to manufacture.

SMT & Through-Hole Assembly

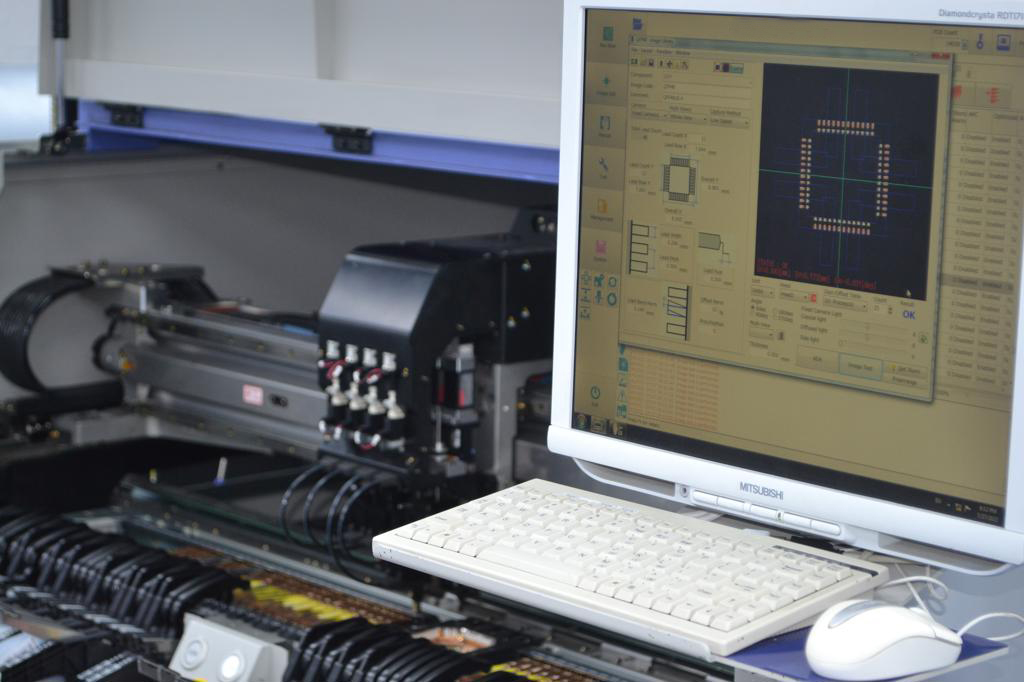

Our automated assembly equipment gives us the ability to manufacture a wide range of electronic products at high speed and accuracy from prototyping through to full volume production.

- Component size from 0201 – large BGA, QFP & QFN placement

- Automated Screen Printing

- Fully automated surface mount and through hole PCB assembly

- High accuracy BGA placement

- Full in-house test capability

- Functionality testing

- Wiring and looming manufacture

- Enclosure assembly

- Total procurement and kitting service

- Rework & repair

We move fast. All we need in order to price up an assembly job are the Gerber files for the PCB and the Bill of Materials (list of components). We can usually provide you with a quotation within 24 hours of receiving these. And if you decide to go ahead, our flexible scheduling allows us to start building your job as soon as the parts arrive, so you receive the best possible service.

You can email the relevant details to us, or give us a call on 01788 860101 to discuss it first if you prefer.

PCB Repair and Rework

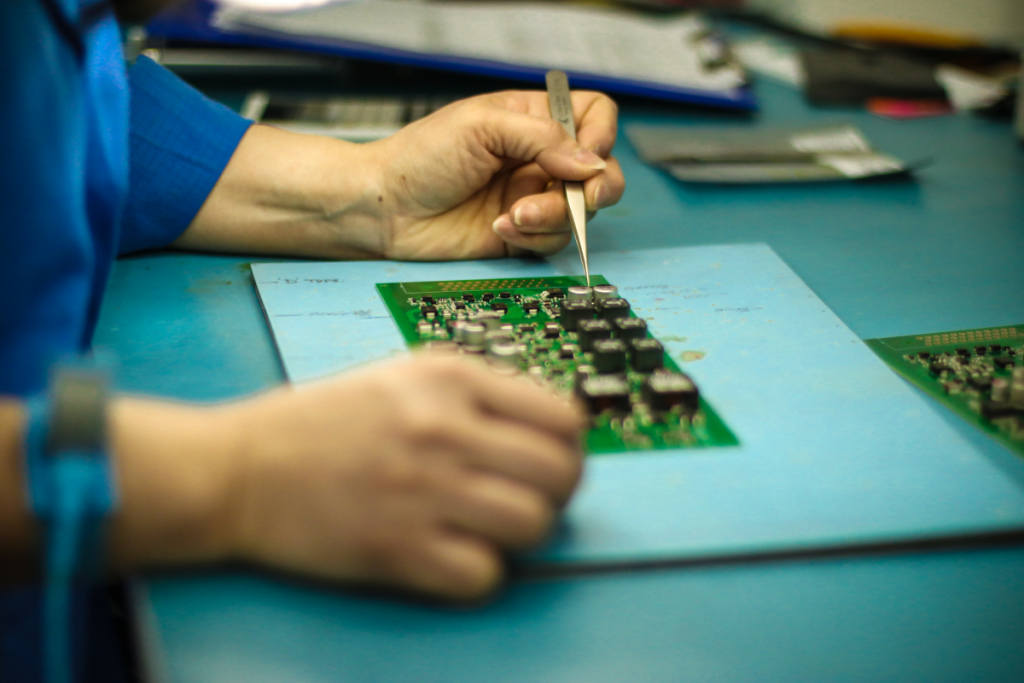

Fully populated PCBs can be reworked at our in-house repair facility under IPC J-STD-001. With the aid of our optical enhancement equipment, we can work with parts which are almost invisible to the naked eye.

- ICs and BGAs can be removed from PCBs and replaced

- Valuable ICs and BGAs can be removed from PCBs and cleaned up for use on new boards

- PCB tracks can be repaired.

- Discrete components down to 0201 can be removed and replaced

- X-ray analysis of boards can be undertaken

It is often the case that re-work of expensive boards is more cost effective than replacement.

Full Product Design & Test

Products can be assembled using free-issued components or fully procured. Our pick-and-place equipment is capable of placing up to 5,500 components per hour, so you are assured of a fast turnaround and a quality result. Once assembled, PCBs are inspected, tested and can be mounted into enclosures. Just send us your bill-of-materials (BOM) and gerber files, and let us do the rest.

Other services include cable assemblies, potting and conformal coating.

- Component size from 0201 – large BGA & QFP placement

- Automated Screen Printing

- Manual surface mount & PTH assembly for prototypes

- Fully automated surface mount and through hole PCB assembly

- High accuracy BGA placement

- Full in-house test capability

- Functionality testing

- Wiring and looming manufacture

- Enclosure assembly

- Total procurement and kitting service

- Rework & repair

We move fast. All we need in order to price up a normal assembly job are the Gerber files for the PCB and the Bill of Materials (list of components), plus any build instructions. We can usually provide you with a quotation within 24 hours of receiving these. And if you decide to go ahead, our flexible scheduling allows us to start building your job as soon as the parts arrive, so you receive the best possible service.

You can email the relevant details to us, or give us a call on 01788 860101 to discuss it first if you prefer.

Capabilities

Draycote Technology’s PCB manufacturing and assembly capabilities encompass a wide range of services and specifications to meet your project requirements.

Read More

Read More

Here is a comprehensive list of our capabilities:

- Single-sided, double-sided, and multi-layer PCBs

- Rigid, flexible, and rigid-flex PCBs

- High-density interconnect (HDI) PCBs

- Large non-standard PCBs up to 1.2m

- LED Boards

- Surface Mount Technology (SMT) assembly

- Component size from 01005 – large BGA, QFP & QFN placement

- Through-hole assembly

- Mixed technology assembly (SMT and through-hole combined)

- Fine pitch component placement

- Ball Grid Array (BGA) assembly

- Package-on-package (PoP) assembly

- Flip-chip assembly

- Automated component placement

- High-precision solder paste application

- Vapour Phase Reflow soldering.

- Wave soldering

- Hand soldering for specialised components or rework

- Fine-pitch components

- BGA and QFN components

- Connectors and sockets

- In-circuit testing (ICT)

- Functional testing

- Automated Optical Inspection (AOI)

- X-ray inspection for BGA and solder joint analysis (external)

- Electrical testing and validation

- Adherence to IPC-A-600 and IPC-A-610 standards

- ISO 9001 certified quality management system

- RoHS compliance for lead-free manufacturing

- UL certification for specific applications

These capabilities reflect our commitment to delivering high-quality, reliable, and technologically advanced PCB solutions.

Our experienced team is dedicated to partnering with you to bring your designs to life and meet your specific project requirements.

Contact us today to discuss your PCB requirements and take advantage of our comprehensive capabilities.

About Us

Draycote Technology offers PCB population and assembly, from design to prototyping through to full volume production and assembly. We specialise in small to medium volume production, always with the emphasis firmly on high quality and meeting the delivery deadline. Our new production facility is fully anti-static protected.

Why Choose Us

UK Manufacturer

Giving you flexibility and increased cash flow control.

Quick Turnaround

We move fast. Flexible scheduling allows us to start building your job as soon as the parts arrive.

Less risk in the supply chain

With shorter lead times and smaller MOQs.

Better Communication

As a UK supplier we have a full understanding of your market.

Our automated production equipment gives Draycote Technology the speed and flexibility to supply a wide range of products to a variety of different industries. Our team of highly skilled engineers has many years of experience in the electronics industry. We focus strongly on quality and keeping the cost of manufacturing down, in addition to offering a quick response and rapid turnaround for your product.

Draycote Technology can produce PCB assemblies in quantities from one-off to tens of thousands per month. We are a UK manufacturer, with all our production facilities in-house and on one site.

We also have the ability to recover ICs and BGAs from existing boards. With the current component shortage and high part prices, it makes sense to rework old PCBs or just recover the valuable parts from them for reuse.

Get in touch

Contact us

- Tripontium Business Centre, Newton Lane, Rugby, Warwickshire, CV23 0TB, England

- enquiries@draycotetechnology.com

- 01788 860101

Talk to us

Where to find us

We work fast

Draycote Technology is an ISO 9001: 2015 certified company

ISO 9001:2015 is the international standard that defines the requirements for a Quality Management System (QMS).

Draycote Technology meets this standard which demonstrates our ability to consistently provide products and services that meet customer and applicable statutory and regulatory requirements. This enhances customer satisfaction through the effective application of the system, including processes for improvement of the system and the assurance of conformity to customers and applicable statutory and regulatory requirements.